Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Noticias

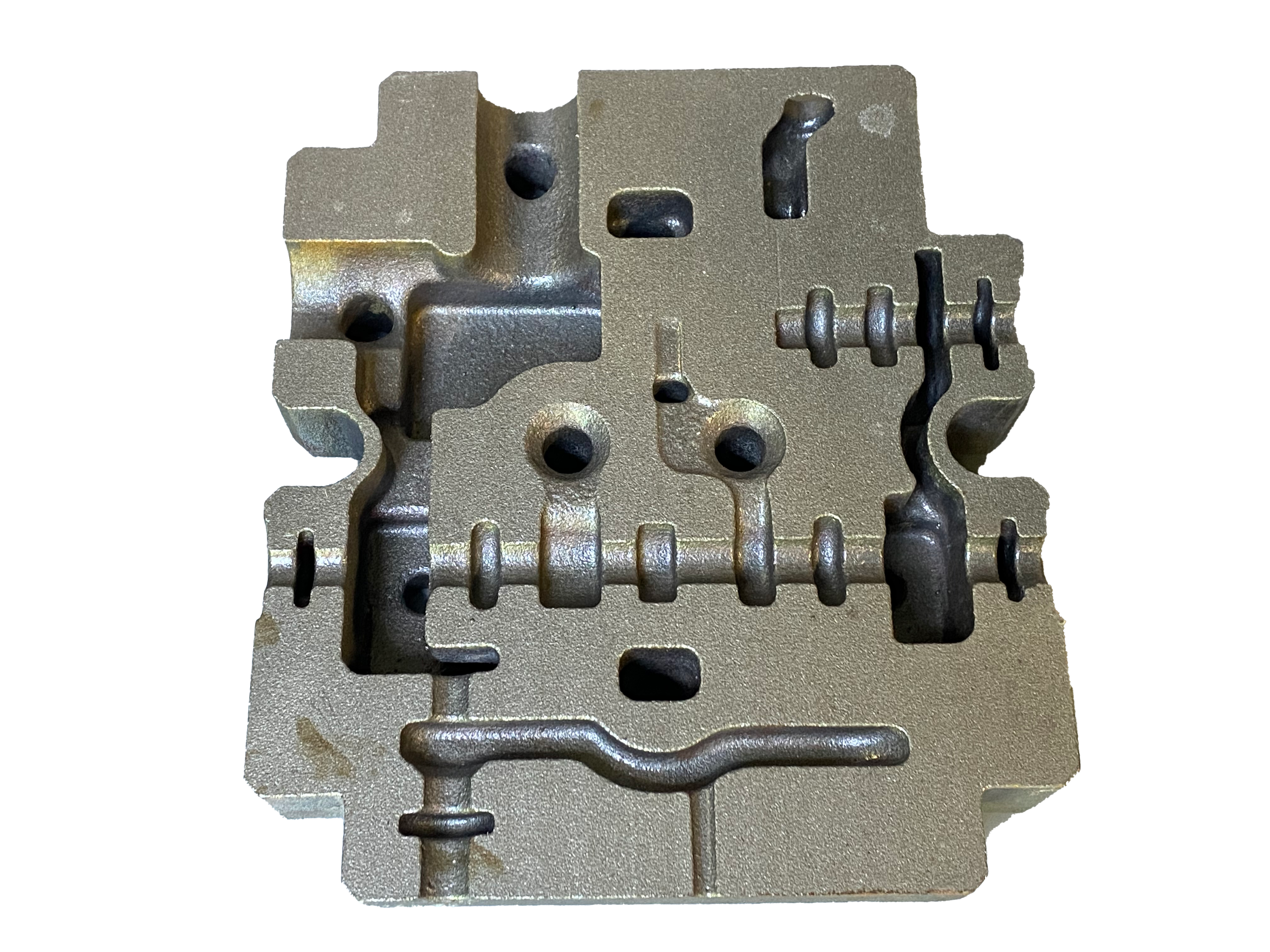

Heat Treatment of Cast Iron

In addition to selecting the optimum composition to obtain a certain structure, heat treatment is also an important way to further adjust and improve the matrix structure to improve the properties of cast iron.

Generally, the heat treatment of cast iron can not improve the morphology and distribution of graphite in the original structure. For grey cast iron, the stress concentration effect caused by flake graphite is the main factor that plays a leading role in the properties of cast iron. Therefore, the strengthening effect of heat treatment on grey cast iron is far less significant than that of steel and ductile iron. The heat treatment process of Guyou cast iron mainly includes annealing, normalizing, etc. For nodular cast iron, because the graphite is spherical, the cleavage effect on the matrix is greatly reduced. Through heat treatment, the base structure can play a full role, which can significantly improve the mechanical properties of nodular cast iron. Therefore, like steel, the heat treatment processes of ductile iron include annealing, normalizing, quenching and tempering, multi-temperature quenching, induction heating quenching, and surface chemical heat treatment.

The heat treatment process of cast iron:

- stress relief annealing

Due to the uneven wall thickness of the casting, the effect force and structural stress will be produced during the heating, cooling, and phase transformation. In addition, large parts are also prone to residual stress after machining, and all these internal stresses must be eliminated. The usual heating temperature for stress relief annealing is 500 ~ 550 ℃, the holding time is 2 ~ 8h, and then furnace cooling (gray iron) or air cooling (ductile iron). 90 ~ 95% of the internal stress of the casting can be eliminated by this process, but the structure of the cast iron does not change. If the temperature exceeds 550 ℃ or the holding time is too long, it will cause graphitization and reduce the strength and hardness of the casting.

- high-temperature graphitizing annealing for eliminating white spots in castings

When the casting is cooled, the surface layer and thin section often produce white spots. The white mouth structure is hard and brittle with poor processability and easy to peel off. Therefore, annealing (or normalizing) must be used to eliminate the white structure. The annealing process is as follows: heating to 550-950 ℃ for 2-5 hours, then furnace cooling to 500-550 ℃, and air cooling. During the high-temperature insulation period, the hypercementite and eutectic cementite decompose into graphite and A. in the subsequent cooling protection process, the secondary cementite and eutectoid cementite also decompose, resulting in the graphitization process. Due to the decomposition of cementite, the hardness decreases, and the machinability is improved.

- normalizing of ductile iron

The purpose of normalizing ductile iron is to obtain pearlitic matrix structure and refine grain size and uniform structure, to improve the mechanical properties of castings. Sometimes, normalizing is also the preparation for the structure of ductile iron surface quenching. Normalizing can be divided into high-temperature normalizing and low-temperature normalizing. The high-temperature normalizing temperature is generally not more than 950 ~ 980 ℃, and the low-temperature normalizing is generally heated to the fold temperature range of 820 ~ 860 ℃. Generally, four persons are required to deal with after normalizing to eliminate the internal stress generated during normalizing.

- quenching and tempering of ductile iron

To improve the mechanical properties of ductile iron, the castings are generally heated to 30 ~ 50 ℃ above Afc1 (Afc1 represents the end temperature of a formation during heating) and quenched into oil after heat preservation to obtain martensitic structure. To properly reduce the residual stress after quenching, tempering should be carried out after quenching. The low-temperature tempering structure is tempered martensite plus residual bainite and spheroidal graphite. This structure has good wear resistance and is used for parts requiring high wear resistance and high strength. The medium temperature tempering temperature is 350-500 ℃. After tempering, the microstructure is tempered troostite plus spheroidal graphite. It is suitable for thick parts requiring good wear resistance, certain effective stability, and elasticity.

- multi-temperature quenching of ductile iron

After austempering, ductile iron can obtain high strength, good plasticity, and toughness. The choice of heating temperature for multi-temperature quenching mainly considers that the original structure is A-shaped, no residual f is left, and then a grain growth is avoided at the same time. The heating temperature is generally 30 ~ 50 ℃ above Afc1, and the isothermal treatment temperature is 0 ~ 350 ℃ to ensure the lower bainite structure with comprehensive mechanical properties. After austempering of rare earth mg Al ductile iron σ b=1200~1400MPa, α k=3~3.6J/cm2, HRC=47~51。 However, it should be noted that a tempering process should be added after isothermal quenching.

- surface quenching

To improve the surface hardness, wear resistance, and fatigue strength of some castings, surface quenching can be used. Both gray cast iron and ductile iron castings can be surface quenched. Generally, high (medium) frequency induction heating surface quenching and electric contact surface quenching are used.

- chemical heat treatment

For castings requiring wear resistance, oxidation resistance, and corrosion resistance on the surface, a chemical heat treatment process similar to steel can be adopted, such as gas soft chlorination, chlorination, boriding, sulfurizing, etc.

Searching for a cast iron furnace, cast iron sand, oval cast iron from China, you can get high-quality products at a nice price.